Fixing Common Pull-Start Problems on Small Engines

Pull-start (recoil) systems are simple, reliable, and found on most small outboards, generators, and garden engines. When they fail, it’s usually due to wear, dirt, or corrosion rather than serious engine trouble. The good news? Most pull-start problems are easy and cheap to fix at home.

This guide walks through the most common pull-start faults, how to diagnose them, and how to fix them safely.

How a Pull-Start Works (Quick Overview)

- A pull-start system uses:

- A starter rope

- A recoil spring

- A pulley

- Starter pawls or dogs

When you pull the cord, the pulley turns the flywheel, spinning the engine. The spring then rewinds the rope ready for the next pull.

If any part of this system fails, starting becomes difficult or impossible.

Common Pull-Start Problems & Fixes

1. Pull Cord Won’t Pull (Engine Locked)

Possible causes:

- Engine is hydro-locked (water in cylinder)

- Seized engine

- Jammed starter pawls

- Rusted flywheel

Fix:

- Remove the spark plug

- Try pulling the cord again

- If water sprays out → dry cylinder and investigate water ingress

- If still locked → check flywheel and starter dogs

⚠️ Never force the cord — you’ll snap the rope or damage the spring.

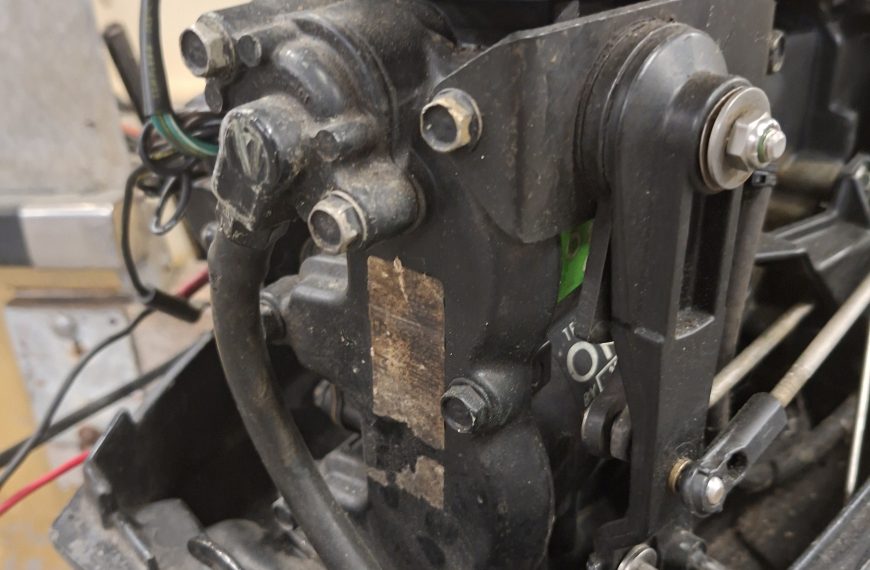

2. Cord Pulls but Doesn’t Engage the Engine

Possible causes:

- Worn or stuck starter pawls

- Broken recoil engagement clips

- Dirt or salt corrosion

Fix:

- Remove starter housing

- Clean pawls with carb cleaner

- Lightly oil pivot points

- Replace worn or cracked pawls

💡 Saltwater engines suffer this problem frequently.

3. Cord Doesn’t Retract (Slack Rope)

Possible causes:

- Broken recoil spring

- Spring jumped out of its housing

- Dirt or rust in the pulley

Fix options:

- Clean and re-tension the spring

- Replace the recoil spring if snapped

- Clean pulley and housing thoroughly

🛠 Tip: Recoil springs are cheap but fiddly — gloves and eye protection recommended.

4. Rope Snaps or Frays Repeatedly

Possible causes:

- Old, brittle rope

- Sharp edges on pulley

- Rope rubbing against housing

Fix:

- Replace with correct diameter starter cord

- Smooth sharp edges with fine sandpaper

- Route rope exactly as original

🚫 Do not use normal household rope — it won’t last.

5. Pull-Start Feels Rough or Jerky

Possible causes:

- Corrosion inside housing

- Bent pulley

- Flywheel resistance (ignition or compression issue)

Fix:

- Strip and clean starter assembly

- Check flywheel nut torque

- Inspect ignition timing if resistance feels abnormal

6. Starter Pulls But Slips Back Violently

Possible causes:

- Kickback from incorrect timing

- Sheared flywheel key

- Ignition advance fault

Fix:

- Inspect flywheel key

- Replace if damaged

- Check ignition components

⚠️ This fault can break wrists — fix before further use.

Tools You’ll Usually Need

- Socket set or spanners

- Screwdrivers

- Starter rope

- Carb cleaner or WD-40

- Light grease or oil

- Gloves & eye protection

Preventing Pull-Start Problems

- Rinse saltwater engines after use

- Occasionally remove starter housing and clean

- Don’t let the rope snap back — guide it in

- Store engines dry and upright

- Lubricate pawls lightly (not heavily)

When to Replace the Whole Assembly

Consider replacement if:

- Housing is cracked

- Pulley is warped

- Spring housing is badly corroded

- Parts are obsolete and unavailable

Sometimes a complete recoil unit is cheaper than parts.